Hoses

Hydraulic hoses are sized by their inner diameter (I.D.), flow rate and fluid types. The fittings/adapters are seized by the metal tube outside diameter (O.D.).

You will find the inside diameter printed on the hose. For example 1/4" or 5/16”. The inside diameter may also be listed using a DIN notation like “DN06 L” (see table below).

The I.D. can be specified as inches be a fraction or a decimal like 1/4 or 0.25, in millimeters as 6.4mm (1/4). The markings "DN" stand for diameter nominal (Nominal) size notation. The letters "DN" are followed by the nominal diameter in mm. For example "DN6" means 6mm of nominal diameter. We find "DN" on metric hoses using the DIN 2353 standards. A SAE hose will use a dash size (SAE size) notation. A dash is a count of 1/16ths, for example a 3/4" I.D. is written as -4 (notice the dash). British hose will use the "G" notation.

| Common hose sizes used in mini excavators. | ||

| I.D. mm | I.D. in | Dash/SAE |

| 6, 6.3 | 1/4 | -4 |

| 8 | 5/16 | -5 |

| 10 | 3/8 | -6 |

| 12 | 1/2 | -8 |

| 16 | 5/8 | -10 |

| 19 | 3/4 | -12 |

| 25 | 1 | -16 |

Mini excavators from China will 99% of the time use DIN 2353 hoses that follow the EN857 specification.

You will find four types of EN857 hoses used on mini excavators. EN857 2SN, EN857 2SC and EN857 2SC, EN857 1SC. The EN 853 hoses are at minimum reinforced with a steel wire mesh. The type number “2” means it has a double mesh and “1” is for a single mesh. The hoses with the “SC” type will have smaller outside diameters than a “SN” hose and you will see them more often on minis. Hoses with the text “SAE100R2”, “SAE100R1” should be equivalent to the “SN” types in EN857.

A hose or fitting is classified by their operating range. These ranges are "light", “medium” or "heavy".

|

Series |

Description |

Working Pressure |

|

LL |

Light |

100 Bars / 1450 psi |

|

L |

Medium |

315 Bars / 4568.69 psi |

|

S |

Heavy |

630 Bars / 9137.38 psi |

We refer to these ranges as “series”, for example a hose is in the “L Series”.

Depending on the materials and reinforcement a hose may withstand more pressures. For example a two wire mesh reinforced hose may go over 5000 psi. A convention on quality hoses is to add the letters “WP” in front of the pressure printed on the hose to indicate it is the working pressure.

TODO: Explain BSP fittings (threads) found on ball valves, solenoid diverter valves, some pilot controls, some attachments (hammers), and some pumps.

Identifying a DIN 2353 24° Metric Tube Fitting

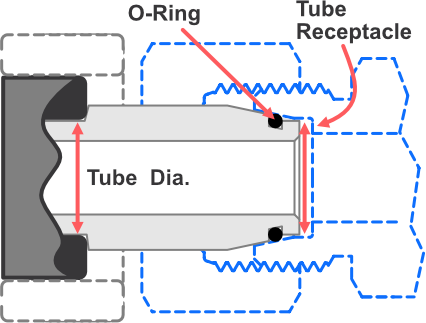

The tube diameter or bore size is the most important information we need to identify the fitting. A 2345 fitting will have a flat rest or receptacle where the bore mates with the fitting.

The measurement of the receptacle is actually the diameter of the metal tube that goes in the hose and is crimped by the fitting. If the fitting receptacle measures 10 mm then the crimp fitting has a 10 mm metal tube.

For example a common mini excavator hose is a 5/16” or 7.95 mm inside diameter (I.D.). A fitting for this hose will use a tube of 10 mm which gives about 1 mm on each side for the stretch. Another example is the 1/4" ID hose which is 6 mm and will use a 8 mm tube on the fittings.

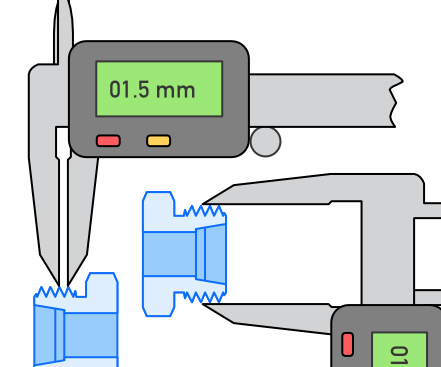

The next thing we need to do is figure out the thread type. On 1 ton mini excavators we use “L” series fittings (medium duty), that means that a thread may only have a 1.5 or 2.0 pitch.

The pitch is the distance between the threads. Measure from one crown to another or from valley to the next.

Here we should get something very close to 1.5 mm or to 2 mm.

If you get something close to 1 mm then you have a “LL” (Light duty) hose. But for the sake of this guide we will not cover those hoses.

Then we measure the OD of the thread. If the OD of the thread is 16 mm that means we have a “M16 x 1.5” thread.

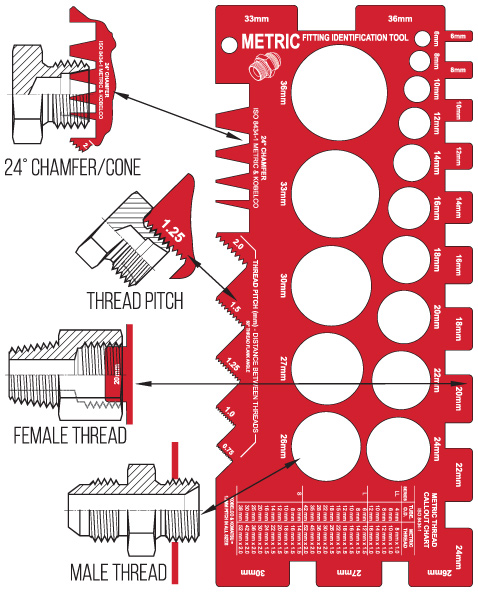

A cool tool to buy is a thread gauge.

Using the thread gauge is very simple.

Use the ridges to test if a thread pitch is 1.5 or 2 mm.

Use the stubs on the other side to see the tube diameter. Use the stub that fits the most and reaches the deeper.

Use the holes to measure the thread OD.

You can buy these on Amazon.

These are the DIN 24° Cone fittings that you are more likely to find in your mini excavator:

|

Tube OD |

Thread Callout |

Hose ID |

| 6 mm | M12 x 1.5 | 1/4 in |

| 8 mm | M14 x 1.5 | 1/4 in |

| 10 mm | M16 x 1.5 | 5/16 in |

| 12 mm | M18 x 1.5 | 3/8 in |

| 15 mm | M22 x 1.5 | 1/2 in |

| 18 mm | M26 x 1.5 | 5/8 in |

| 22 mm | M30 x 2 | 3/4 in |

| 28 mm | M36 x 2 | 1 in |

Common fittings you will find in your mini excavator.

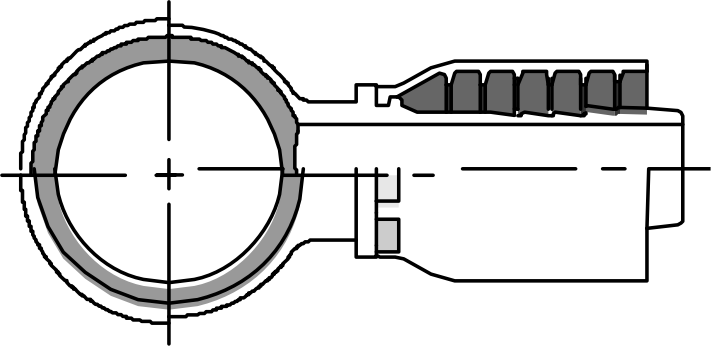

Crimp Hose End

Female Swivel

Metric Flare

24° Cone

DIN L (Medium Pressure)

with O-Ring

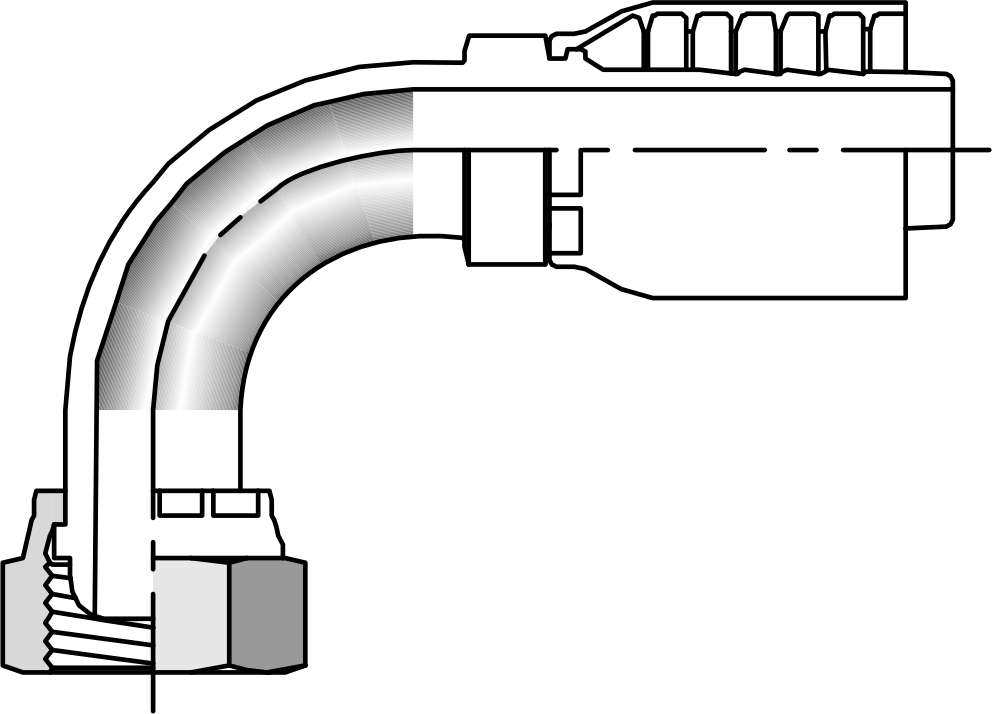

Crimp Hose End

Female Swivel, 90˚ Elbow

Metric Flare

24° Cone

DIN L (Medium Pressure)

with O-Ring

Crimp Hose End

Female Swivel, 45˚ Elbow

Metric Flare

24° Cone

DIN L (Medium Pressure)

with O-Ring

Banjo Hose End

Used on the connection to DCV block.

Metric Flare

24° Cone

DIN L (Medium Pressure)

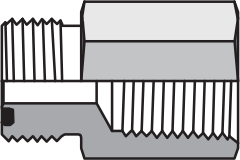

Unions, Reducers and Adapter

These allow you to change from one thread size to another.

Change from a DIN 2353 (Metric) connection to a BSSP (British) connection commonly found in some valves and attachment tools like hammers.

XCAV © 2024 miniexcav.com